Abstract

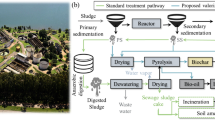

Although nowadays landspreading and incineration are the conventional disposal methods for the primary sludge (PS) and biosludge (BS) generated in the wastewater treatment plants of the pulp mill industry in Uruguay, their direct incineration for energy recovery is the most preferable one. Here, we propose the hydrothermal carbonization (HTC) method as a pre-treatment to improve the fuel characteristic of PS and BS. Proximate and ultimate analysis, scanning electron microscopy, and thermogravimetric analysis show that the HTC affects PS and BS differently regarding carbon fixation, energy densification and energy conversion efficiency. Moreover, ash composition measured by X-ray fluorescence indicates that the HTC effectively diminishes the slagging and fouling indexes for both feedstocks, which can increase the life expectancy of boilers. Alternative PS, BS, and their hydrochars were activated with H3PO4 to produce activated carbons, i.g. the BET specific surface area was as high as 800 m2/g for PS-AC, and exhibits CO2 adsorption capacity of 5 mmol/g at 10 bar at 273 K. These studies provide alternatives to direct incineration and landspreading of PS and BS in Uruguay to reduce their environmental impact, either by enhancing their fuel quality or by converting them into much more valuable products to face air pollution.

Graphical Abstract

Similar content being viewed by others

Data Availability

Not applicable.

Code Availability

Not applicable.

Notes

ADt: air dry ton.

Ley 15.921 del 17 de diciembre de 1987, y su Decreto Reglamentario 454/88 del 8 de julio de 1988,

Ley 15.939 del 28 de diciembre de 1987 y modificativas, y su Decreto reglamentario 452/88 del 6 de julio de 1988 y modificativos.

References

Planta de celulosa con tecnología de vanguardia. https://www.upmpasodelostoros.com/es/planta-de-celulosa/. Accessed 14 Mar 2023

Montes del Plata. Producción sustentable. https://www.montesdelplata.com.uy/espanol/. Accessed 14 Mar 2023

C. Amorin. https://www.ambiente.gub.uy/oan/wp-content/uploads/2018/02/VAL_Planta-de-celulosa-Paso-de-los-Toros-.pdf. Accessed 1 Nov 2022

Bentancur, S., López-Vázquez, C.M., García, H.A., Duarte, M., Travers, D., Brdjanovic, D.: Modelling of a pulp mill wastewater treatment plant for improving its performance on phosphorus removal. Process Saf. Environ. Prot. 146, 208–219 (2021). https://doi.org/10.1016/j.psep.2020.08.029

Mohammadi, A., Sandberg, M., Venkatesh, G., Eskandari, S., Dalgaard, T., Joseph, S., Granström, K.: Environmental analysis of producing biochar and energy recovery from pulp and paper mill biosludge. J. Ind. Ecol. 23(5), 1039–1051 (2019). https://doi.org/10.1111/jiec.12838

Martínez, J., Mallo, M., Lucas, R., Álvarez, J., Salvarrey, A., Gristo, P. Guía para la gestión integral de residuos peligrosos. Fundamentos. Tomo I. (2005) https://www.cempre.org.uy/docs/biblioteca/guia_para_la_gestion_integral_residuos/gestion_respel01_fundamentos.pdf. Accessed 1 Nov 2022

Sevilla, M., Fuertes, A.B.: Chemical and structural properties of carbonaceous products obtained by hydrothermal carbonization of saccharides. Chem. Eur. J. 15(16), 4195–4203 (2009). https://doi.org/10.1002/chem.200802097

Libra, J.A., Kyoung, S.R., Kammann, C., Funke, A., Berge, N.D., Neubauer, Y., Titirici, M.M., Fühner, C., Bens, O., Kern, J., Emmerich, K.H.: Hydrothermal carbonization of biomass residuals: a comparative review of the chemistry, processes and applications of wet and dry pyrolysis. Biofuels 2(1), 71–106 (2014). https://doi.org/10.4155/bfs.10.81

Jain, A., Balasubramanian, R., Srinivasan, M.P.: Hydrothermal conversion of biomass waste to activated carbon with high porosity: A review. Chem. Eng. J. 283, 789–805 (2016). https://doi.org/10.1016/j.cej.2015.08.014

Ischia, G., Fiori, L.: Hydrothermal carbonization of organic waste and biomass: A review on process, reactor, and plant modeling. Waste Biomass Valoriz. 12, 2797–2824 (2021). https://doi.org/10.1007/s12649-020-01255-3

Hu, B., Wang, K., Wu, L., Yu, S.H., Antonietti, M., Titirici, M.M.: Engineering carbon materials from the hydrothermal carbonization process of biomass. Adv. Mater. 22(7), 813–828 (2010). https://doi.org/10.1002/adma.200902812

Lu, X., Berge, N.D.: Influence of feedstock chemical composition on product formation and characteristics derived from the hydrothermal carbonization of mixed feedstocks. Bioresour. Technol. 166, 120–131 (2014). https://doi.org/10.1016/j.biortech.2014.05.015

Saha, N., Saba, A., Saha, P., McGaughy, K., Franqui-Villanueva, D., Ortz, W.J., Hart-Cooper, W., Reza, T.M.: Hydrothermal carbonization of various paper mill sludges: An observation of solid fuel properties. Energies 12(5), 858 (2019). https://doi.org/10.3390/en12050858

Monte, M.C., Fuente, E., Blanco, A., Negro, C.: Waste management from pulp and paper production in the European Union. Waste Manag. 29(1), 293–308 (2009). https://doi.org/10.1016/j.wasman.2008.02.002

Wilk, M., Śliz, M., Lubieniecki, B.: Hydrothermal co-carbonization of sewage sludge and fuel additives: Combustion performance of hydrochar. Renew. Energy 178, 1046–1056 (2021). https://doi.org/10.1016/j.renene.2021.06.101

Mureddu, M., Dessì, F., Orsini, A., Ferrara, F., Pettinau, A.: Air- and oxygen-blown characterization of coal and biomass by thermogravimetric analysis. Fuel 212, 626–637 (2018). https://doi.org/10.1016/j.fuel.2017.10.005

Zhang, Y., Guo, Y., Cheng, F., Yan, K., Cao, Y.: Investigation of combustion characteristics and kinetics of coal gangue with different feedstock properties by thermogravimetric analysis. Thermochim. Acta 614, 137–148 (2015). https://doi.org/10.1016/j.tca.2015.06.018

Yang, S., Lei, M., Li, M., Liu, C., Xue, B., Xiao, R.: Comprehensive estimation of combustion behavior and thermochemical structure evolution of four typical industrial polymeric wastes. Energies 15(7), 2487 (2022). https://doi.org/10.3390/en15072487

Pronobis, M.: Evaluation of the influence of biomass co-combustion on boiler furnace slagging by means of fusibility correlations. Biomass Bioenerg. 28(4), 375–383 (2005). https://doi.org/10.1016/j.biombioe.2004.11.003

Rouquerol, J., Llewellyn, P., Rouquerol, F.: Is the bet equation applicable to microporous adsorbents. Stud. Surf. Sci. Catal. 160, 49–56 (2007). https://doi.org/10.1016/s0167-2991(07)80008-5

Ruthven, D.M.: Principles of adsorption and adsorption processes. Wiley, New York (1984)

Faroppa, C., Annala, K.: Informe Ambiental. Resumen. Expediente 2004/14001/1/01177. Botnia. 2004. http://www.guayubira.org.uy/celulosa/EIA-Botnia.pdf. Accessed 1 Nov 2022

Inoue, S., Sawayama, S., Dote, Y., Ogi, T.: Behaviour of nitrogen during liquefaction of dewatered sewage sludge. Biomass Bioenergy 12(6), 473–475 (1997). https://doi.org/10.1016/S0961-9534(97)00017-2

He, C., Giannis, A., Wang, J.Y.: Conversion of sewage sludge to clean solid fuel using hydrothermal carbonization: Hydrochar fuel characteristics and combustion behavior. Appl. Energy 111, 257–266 (2013). https://doi.org/10.1016/j.apenergy.2013.04.084

Leng, L., Yang, L., Leng, S., Zhang, W., Zhou, Y., Peng, H., Li, H., Hu, Y., Jiang, S., Li, H.: A review on nitrogen transformation in hydrochar during hydrothermal carbonization of biomass containing nitrogen. Sci. Total Environ. 756, 143679 (2021). https://doi.org/10.1016/j.scitotenv.2020.143679

Zhuang, X., Huang, Y., Song, Y., Zhan, Y., Yin, X., Wu, C.: The transformation pathways of nitrogen in sewage sludge during hydrothermal treatment. Bioresour. Technol. 245, 463–470 (2017). https://doi.org/10.1016/j.biortech.2017.08.195

Xu, Z.-X., Ma, X.-Q., Zhou, J., Duan, P.-G., Zhou, W.-Y., Ahmad, A., Luque, R.: The influence of key reactions during hydrothermal carbonization of sewage sludge on aqueous phase properties: A review. J. Anal. Appl. Pyrol. 167, 105678–105701 (2022). https://doi.org/10.1016/j.jaap.2022.105678

Weiner, B., Poerschmann, J., Wedwitschka, H., Koehler, R., Kopinke, F.D.: Influence of process water reuse on the hydrothermal carbonization of paper. ACS Sustain. Chem. Eng. 2(9), 2165–2171 (2014). https://doi.org/10.1021/sc500348v

Xiao, L.P., Shi, Z.-J., Xu, F., Sun, R.-C.: Hydrothermal carbonization of lignocellulosic biomass. Bioresour. Technol. 118, 619–623 (2012). https://doi.org/10.1016/j.biortech.2012.05.060

Langone, M., Basso, D.: Process waters from hydrothermal carbonization of sludge: characteristics and possible valorization pathways. Int. J. Environ. Res. Public Health 17(18), 6618 (2020). https://doi.org/10.3390/ijerph17186618

Decreto N 253/979. https://www.impo.com.uy/bases/decretos/253-1979. Accessed 1 Nov 2022

Aziz, J.A., Tebbutt, T.H.Y.: Significance of COD, BOD and TOC correlations in kinetic models of biological oxidation. Water Res. 14(4), 319–324 (1980). https://doi.org/10.1016/0043-1354(80)90077-9

Antal, M.J., Grønli, M.: The art, science, and technology of charcoal production. Ind. Eng. Chem. Res. 42(8), 1619–1640 (2003). https://doi.org/10.1021/ie0207919

Canevesi, R.L.S., Schaefer, S., Izquierdo, M.T., Celzard, A., Fierro, V.: Roles of surface chemistry and texture of nanoporous activated carbons in CO2 capture. ACS Appl. Nano Mater. 5(3), 3843–3854 (2022). https://doi.org/10.1021/acsanm.1c04474

Xu, Z.-X., Deng, X.-Q., Zhang, S., Shen, Y.-F., Shan, Y.-Q., Zhang, Z.-M., Luque, R., Duan, P.-G., Hu, X.: Benign-by-design N-doped carbonaceous materials obtained from the hydrothermal carbonization of sewage sludge for supercapacitor applications. Green Chem. 22(12), 3885–3895 (2020). https://doi.org/10.1039/D0GC01272F

Biagini, E., Tognotti, L.: Comparison of devolatilization/char oxidation and direct oxidation of solid fuels at low heating rate. Energy Fuels 20(3), 986–992 (2006). https://doi.org/10.1021/ef0503156

Yang, H., Yan, R., Chen, H., Zheng, C., Lee, D.H., Liang, D.T.: In-depth investigation of biomass pyrolysis based on three major components: hemicellulose, cellulose and lignin. Energy Fuels 20(1), 388–393 (2006). https://doi.org/10.1021/ef0580117

Song, W.J., Tang, L.H., Zhu, X.D., Wu, Y.Q., Zhu, Z.B., Koyama, S.: Effect of coal ash composition on ash fusion temperatures. Energy Fuels 24(1), 182–189 (2009). https://doi.org/10.1021/ef900537m

Pronobis, M., Kalisz, S., Polok, M.: The impact of coal characteristics on the fouling of stoker-fired boiler convection surfaces. Fuel 112, 473–482 (2013). https://doi.org/10.1016/j.fuel.2013.05.044

Miles, T.R., Miles, T.R.J., Baxter, L.L., Bryers, R.W., Jenkins, B.M., Oden, L.L.: Boiler deposits from firing biomass fuels. Biomass Bioenergy 10(2–3), 125–138 (1996). https://doi.org/10.1016/0961-9534(95)00067-4

Lin, Y., Ma, X., Peng, X., Hu, S., Yu, Z., Fang, S.: Effect of hydrothermal carbonization temperature on combustion behavior of hydrochar fuel from paper sludge. Appl. Therm. Eng. 91, 574–582 (2015). https://doi.org/10.1016/j.applthermaleng.2015.08.064

Aliakbari, Z., Younesi, H., Ghoreyshi, A.A., Bahramifar, N., Heidari, A.: Production and characterization of sewage-sludge based activated carbons under different post-activation conditions. Waste Biomass Valoriz. 9(3), 451–463 (2018). https://doi.org/10.1007/s12649-016-9823-7

Thommes, M., Kaneko, K., Neimark, A., Olivier, J.P., Rodríguez-Reinoso, F., Rouquerol, J., Sing, K.S.W.: Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 87(9–10), 1051–1069 (2015). https://doi.org/10.1515/pac-2014-1117

Garrido, J., Linares-solano, A., Martín-Martínez, M., Rodríguez-Reinoso, F., Torregrosa, R.: Use of nitrogen vs carbon dioxide in the characterization of activated carbons. Langmuir 3(1), 76–81 (1987). https://doi.org/10.1021/la00073a013

Casco, M.E., Martínez-Escandell, M., Silvestre-Albero, J., Rodrígue-Reinoso, F.: Effect of the porous structure in carbon materials for CO2 capture at atmospheric and high-pressure. Carbon 67, 230–235 (2014). https://doi.org/10.1016/j.carbon.2013.09.086

Acknowledgements

MEC acknowledges Cristian Toncón for the nitrogen sorption measurements, Dimar Villarroel Rocha for carbon dioxide sorption measurements, Mauricio Ohanian for XRF measurements, Gastón Cubas for providing the residues used as feedstocks. MEC acknowledges the Alexander von Humboldt foundation for the Return Fellowship.

Funding

The Agencia Nacional de Investigación e Innovación for financial support (PD_NAC_2018_1_150145).

Author information

Authors and Affiliations

Contributions

MEC and MD contributed to the study conception and design. Material preparation was performed by VM. Data collection and analysis were performed by MEC, KS and AC. The first draft of the manuscript was written by MEC and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Casco, M.E., Moreno, V., Duarte, M. et al. Valorization of Primary Sludge and Biosludge from the Pulp Mill Industry in Uruguay Through Hydrothermal Carbonization. Waste Biomass Valor 14, 3893–3907 (2023). https://doi.org/10.1007/s12649-023-02105-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-023-02105-8